| NEWS - Introduction to Animal Feed Pellet mill | ||||||||||||||||||||||||||||||||||||||||||

| ¡¡ | ||||||||||||||||||||||||||||||||||||||||||

The feed pellet mill has the following advantages: 1. Avoid animals being picky eaters. 2. High feed return rate; 3. Storage and transportation are more economical; 4. Good liquidity and easy management; 5. Avoid automatic grading of feed ingredients; 6. Eliminate Salmonella in animal feed. So animal feed is made by polymerizing powdered (soybean meal, corn, etc.) or liquid raw materials through our factory's feed pellet mill, suitable for pellet production of feed for pigs, chickens, ducks, fish, shrimp, and ruminants (horses, sheep, rabbits, etc.).

Below is a detailed introduction: Livestock and Poultry Feed Pellet Mill

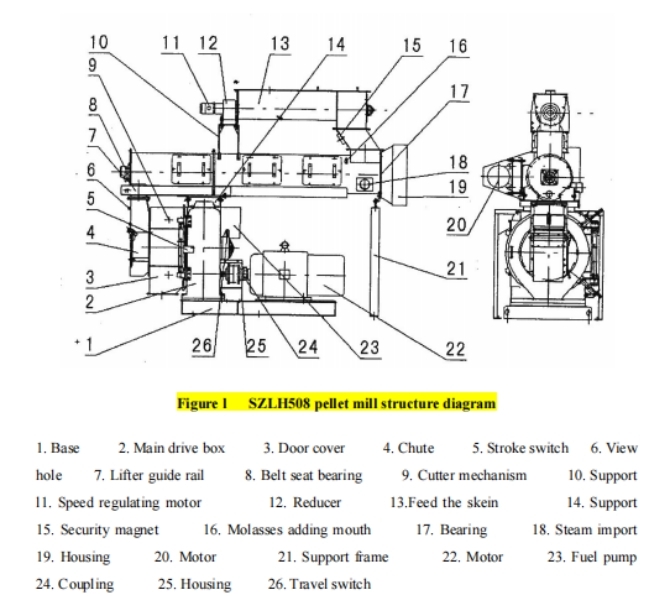

Main structure and working principle The main structure of the pellet mill consists of feeding, stirring, granulation, transmission and lubrication systems. Its working process is to require the water content of no more than 15% of the powder, from the hopper into the feeding loin, by adjusting the speed of the steel-free motor, to obtain the appropriate material flow, through the security magnet to remove the magnetic impurities mixed in the material, and then into the agitator, through the stirring rod mixing and steam mixing for tempering, if it is necessary to add molas or grease, It is also added from the mixing cylinder and tempered with steam (the amount of grease added is generally not more than 3%, otherwise it is difficult to form). After tempered, the temperature of the powder can reach 64 ~ 85¡æ . Humidity up to 14 -16% and then through the chute, and finally into the pressing chamber for pelleting.

Technical Features 1. By using variable speed feeding, the feeding amount can be correctly controlled to meet the production requirements of different particle sizes. 2. Adopting gear direct drive, high precision and efficiency. Compared with belt driven feed pellet machines, the output can be increased by 20%. 3. High quality bearings and motors are used for smooth operation. 4. The main gear and small gear shaft are carbonized and quenched, with high precision, ensuring smooth driving, low noise, and long service life. 5. The ring die and roller assembly can be quickly assembled and disassembled. Common specifications

The common diameters of livestock and poultry pellet feed 1. Diameter of pig feed Milk pig feed with a diameter of 2.5-3mm; Piglet feed with a diameter of 3-3.5mm; Growing pig feed with a diameter of 4-6mm; Sow feed with a diameter of 18-20mm 2. Diameter of chicken feed Chick feed: Crushed feed with a diameter of 3-3.5mm pellets, all passed through a 2.0mm sieve (crushed with a diameter of 2.2-2.5mm); Chicken pre feed for meat: diameter 3-4mm (diameter 4.2-4.5mm crushed); Meat chicken mid to late stage feed: diameter 4-5mm; Egg laying chicken feed and breeding chicken feed: diameter 4-5mm. 3. Duck feed diameter Duckling feed: diameter 3-3.5mm (diameter 2.2-2.5mm); Pre feed for meat ducks: diameter 4mm (diameter 3-3.5mm); Meat duck mid to late stage feed: 6mm (4.2-4.5mm); Egg laying duck feed: diameter 6-8mm (diameter 4.2-4.5mm); 4. Diameter of other animal feed The feed for adult ruminants and young livestock over 2 years old is 4.5-19.0mm. Feed for ruminant young livestock within one year: 4.5-12.0mm; Adult sheep, lactating sheep, and young sheep feed: 4.5-10.0mm; Horse feed: 4.5-19.0mm; Rabbit feed: 0.8-3.0mm. Physical display of the pellet mill

Finally, please feel free to consult us at any time regarding issues related to the pellet mill. LiYang WeiFeng Equipment Co., Ltd info@lywfsb.cn +86 13338795677 www.lywfsb.cn www.lywfsb.com

|