| NEWS - Introduction to Animal Feed Crusher | ||||||||||||||||||||||||||||||||||||||||||

The feed hammer mill has the following advantages: 1. Capable of rapidly pulverizing raw materials such as hay and corn into uniform and fine particles or powders, thereby enhancing feed processing efficiency and quality; 2. The core components are fabricated from premium-grade steel, featuring exceptional wear and corrosion resistance to ensure long-term stable high-performance operation; 3. It can process many kinds of materials, including grain, meal, straw and mineral additive, and has wide adaptability; Animal feed pulverizers are devices that process raw materials such as soybean meal and corn into powdered or granular forms, which are then used for feed pellet production in pigs, chickens, ducks, fish, shrimp, and ruminants (e.g., horses, sheep, rabbits). Below is a detailed introduction: Animal feed crusher

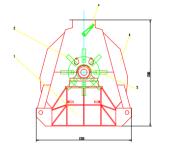

Main structure and working principle The crusher mainly consists of the following key components, as shown in Figure 1.

1. Base 2. Rotor 3. Feed guiding mechanism 4. Operating door 5. Bearing Figure 1. Schematic diagram of the crusher structure Working process The material to be crushed is fed into the machine through the top inlet via a matching feeding mechanism. Guided by the feed guide plate, it enters the crushing chamber from either the left or right side. Under the combined action of high-speed rotating hammer plates and sieve plate friction, the material is gradually crushed. Driven by centrifugal force and airflow, it passes through the sieve holes and is discharged either through the base outlet or the pneumatic conveying base outlet. Technical Features 1. The equipment has a large screening area, fine crushing is not easy to block the screen, the finished product has high fineness and uniform particle size, which is the preferred equipment for the production of fish feed and other aquatic feed. 2. Feeding methods include self-cleaning impeller feeding, belt magnetic separation feeding, and other types. 3. The coarse and fine grinding can be achieved without changing the sieve. 4. The efficiency is increased by more than 25% by using the internal-mould crushing rotor. 5. The elastic screen mechanism prevents material mixing during crushing. 6. It can be equipped with a wind-driven discharge base for easy installation. Common specifications

Physical display

Finally, please feel free to consult us at any time regarding issues related to the crusher. LiYang WeiFeng Equipment Co., Ltd info@lywfsb.cn +86 13338795677 www.lywfsb.cn www.lywfsb.com www.lywf-ringdie.com |