| NEWS - Shaftless screw conveyor |

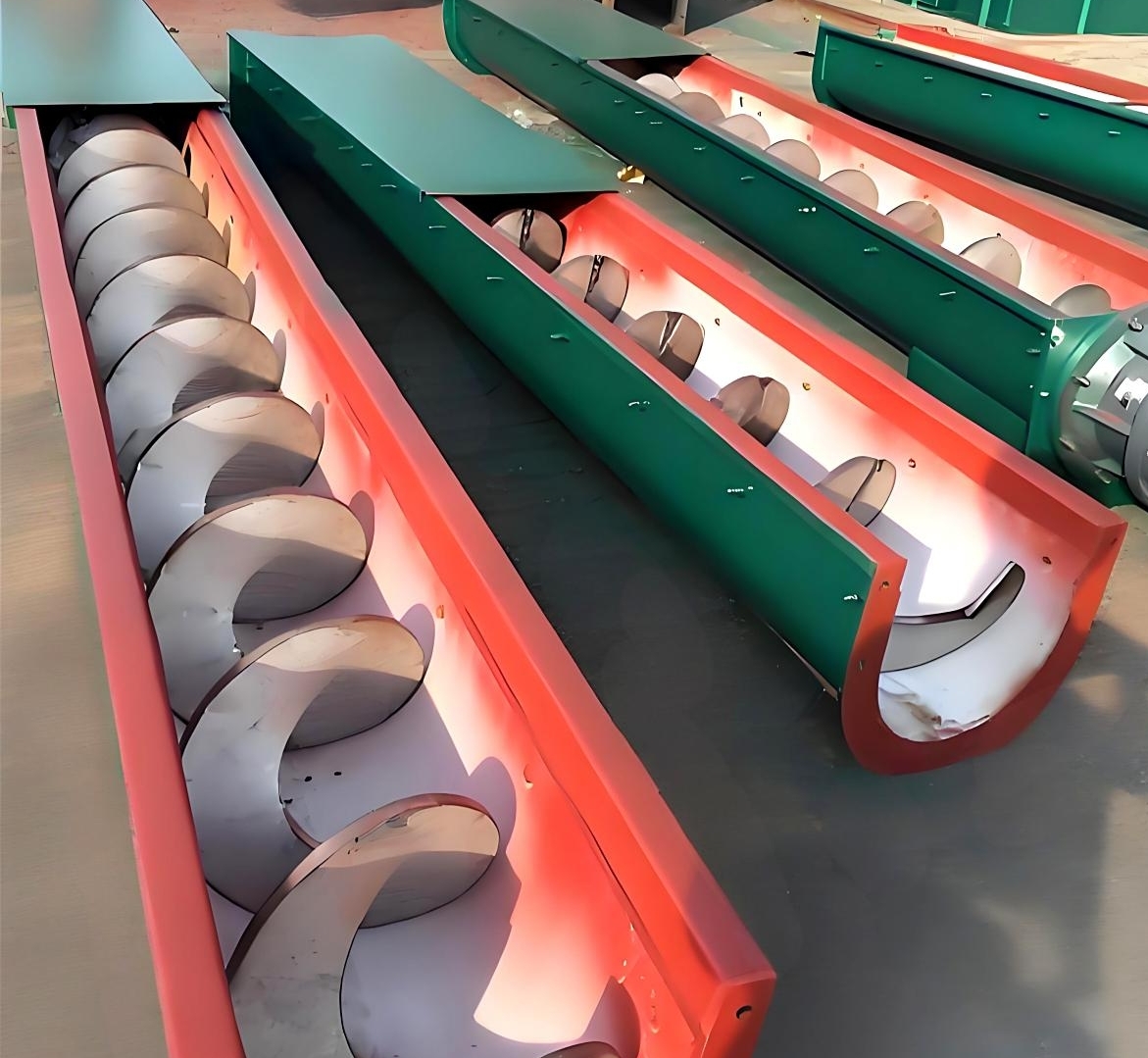

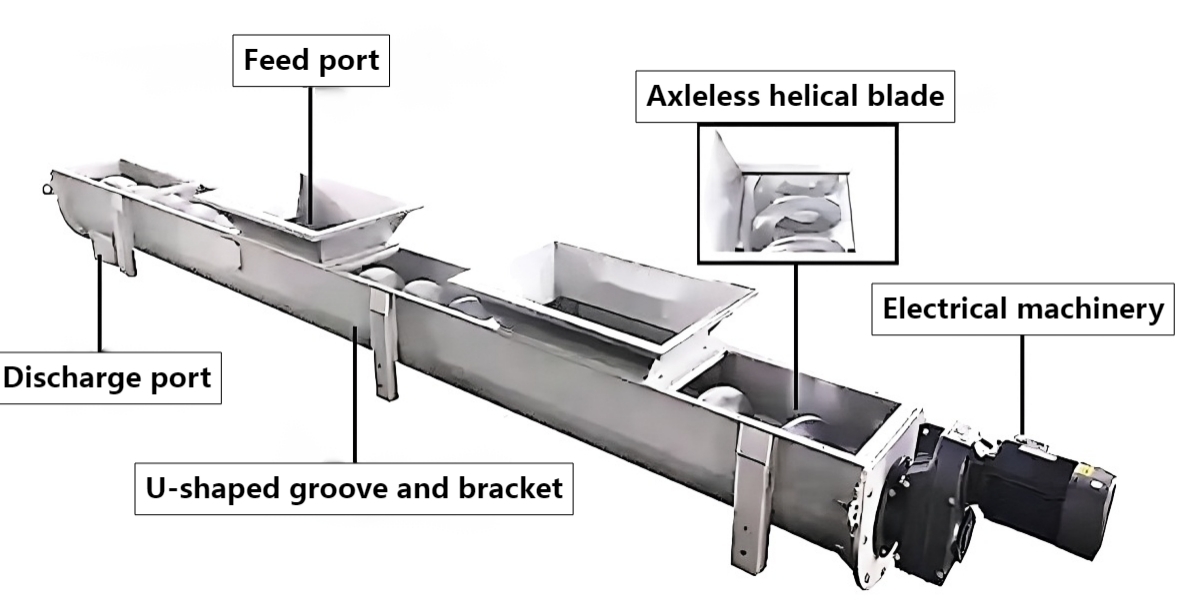

The shaftless screw conveyor is a widely used conveying equipment, commonly employed for transporting materials such as grate slag or sludge. This machine consists of several key components, including the drive mechanism, U-shaped trough and support frame, shaftless screw, liner strips, cover plate, feed opening, discharge opening, and fasteners.

1. Core Structure of Shaftless Screw Conveyor Unlike traditional shafted screw conveyors, the shaftless screw conveyor eliminates the central shaft structure and employs an integrated spiral blade directly wound around the drive end. It primarily consists of the following components: 1.1 Axleless spiral blades: Typically fabricated from high-strength wear-resistant steel or stainless steel, these blades feature a continuous spiral configuration without central support, effectively preventing material entanglement and clogging. 1.2 U-shaped groove body: Serves as a material conveying channel with an inner lining of wear-resistant material (e.g., UHMW polyethylene) to reduce friction resistance. 1.3 The driving device, including motor and reducer, provides the rotating power for the spiral blade. 1.4 Feed and discharge ports: Position and dimensions are designed according to process requirements.

2. Application Scenarios of Shaftless Screw Conveyors 2.1 Sewage treatment plant: Conveying dewatered sludge, screen residue, etc., with high moisture content tolerance (70%~85%). 2.2 Waste Treatment Center: Processes food waste and large debris after crushing to prevent entanglement of plastic bags. 2.3 Agricultural sector: Transportation of biomass materials such as straw and livestock manure. 2.4 Food industry: such as the transportation of high-viscosity materials like tubers and fruit pulp. |